最新訊息

產品

VQ-800, Nano Concrete Densifier (Dry Grinding)

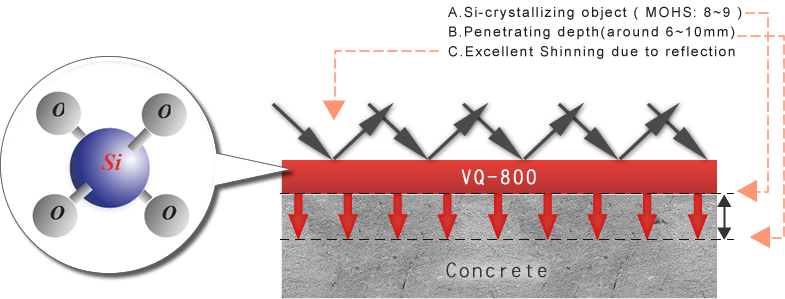

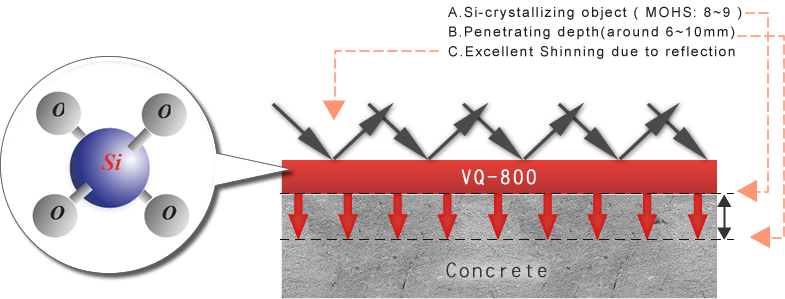

VERQUARE VQ-800 is the Nano Densifier especially designed for the concrete floor with the distinctive performances in the functions of dust-proof, abrasion-resistance, and sealing effect. The raw liquid of VQ-800 is physically transparent, odorless, non-toxic, and non-flammable. After being applied on the concrete, VQ-800 can strongly penetrate into the concrete to a depth of about 6-10 mm from the surface and react with Ca+, Mg+ to form an cross-linking network called “Silicone-crystallizing entity” of which the MOHS value is around 8-9. The “Silicone-crystallizing entity” can efficiently seal the pinholes of the concrete and avoid the particles departing from the surface of the concrete due to weathering.

Applicable Scope

The floors of factories, workshops, supermarkets, logistic warehouses, airport runways, food processing and medicine manufacturing establishments, parking lots, slaughter houses, expressways, bridges, tunnels, ports, sports centers, and etc., which are made of concrete, terrazzo, or emery focusing on the effect of abrasion-proof of the floor.

The Principle of Curing

VQ-800, the Concrete Nano Densifier, can change the structure of the concrete by its effective permeability to conduct a chemical reaction with the original chemical compositions existing in the concrete itself, which can form a compact integral in the three-dimensional space so as to make the micro-interspaces of the concrete smaller and make the gel structure become bigger and stronger so that all kinds of compositions in the concrete can be solidified to a solid entity which is dust-free and compact. Thus, the strength, the hardness, and the abrasion resistance of the concrete floor will get greatly enhanced. In addition, the agent of VQ-800 also can be used to seal up the voids and the gas holes of the concrete so as to avoid the permeation of the pollutants, the grease, and the moisture, which can prevent the particles departing from the voids on the surface of the concrete permanently.

The advantages of VQ-800, the Nano Concrete Densifier

| High Hardness | The MOHS value can achieve 7-9. The hardness value can be upgraded to 3 levels after the application. |

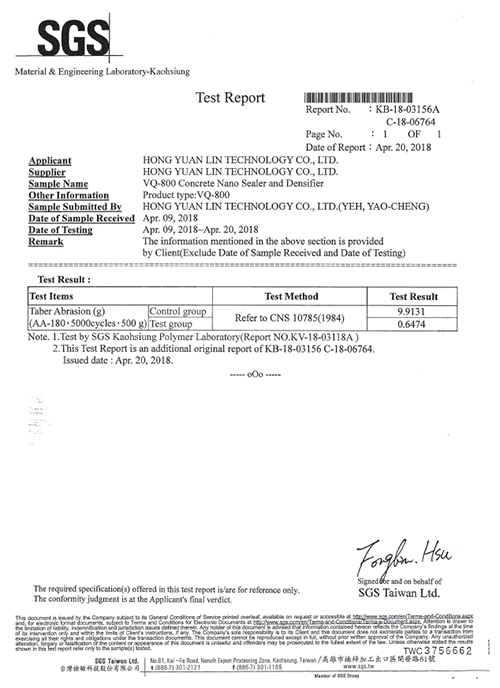

| Abrasion Resistance |

The value of abrasion resistance can be enhanced to over 400% (ASTM C944;1999) |

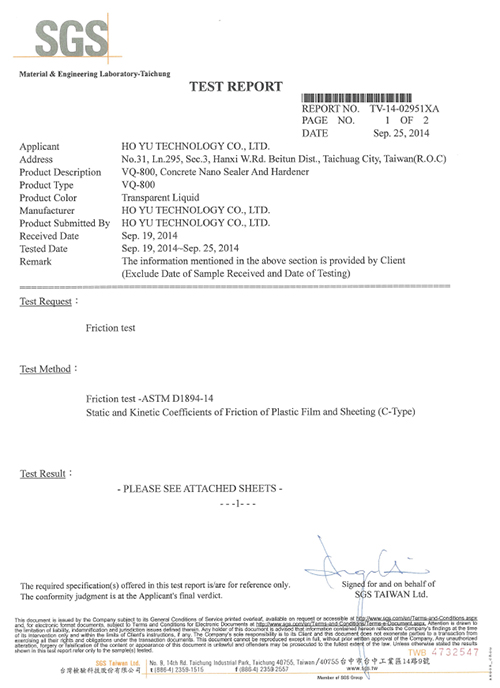

| Non-slip | The dry/wet coefficient of friction > 0.6 (ASTM D1894-14), which can improve the disadvantage of the floor’s slippery problem efficiently. |

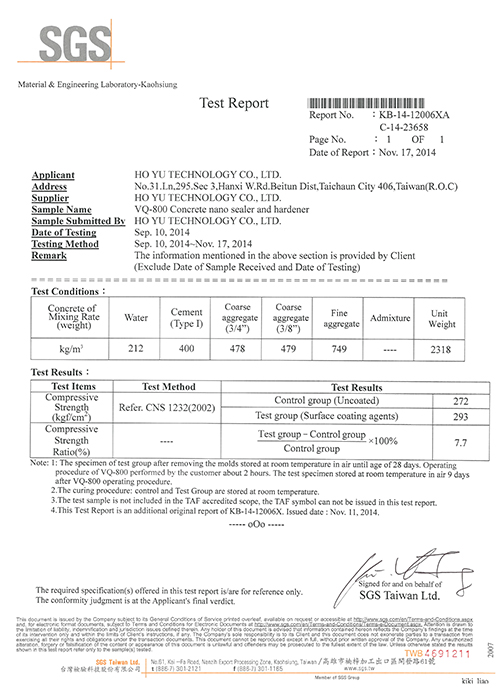

| Compressive Strength | The value of the compressive strength can be increased up to 7.5% according to the standard test of ASTM C39. |

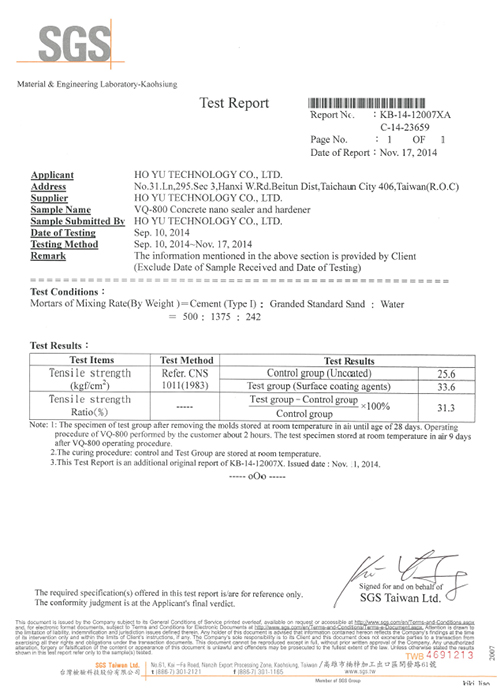

| Tensile Strength | The value of the tensile strength can be increased up to 30% according to the standard test of ASTM C307. |

| Penetration Resistance | The silicone-crystallizing entity can seal the surface of the concrete thoroughly and reduce the permeability of water, oil, and stain efficiently. |

| Dust-proof | Can prevent the particles departing from the voids on the surface of the concrete efficiently so as to enhance the dust-proof effect. |

| High Gloss | After application, the gloss of the concrete will be similar to marbles, and the surface gloss will get higher and higher as time goes by. |

| Weathering Resistance | Can keep Cl+ from passing through the concrete and won’t be affected by UV, water, fog, and electromagnetics. |

| Corrosion Resistance | After treatment, the ability toward the concrete’s corrosion resistance can be largely enhanced. |

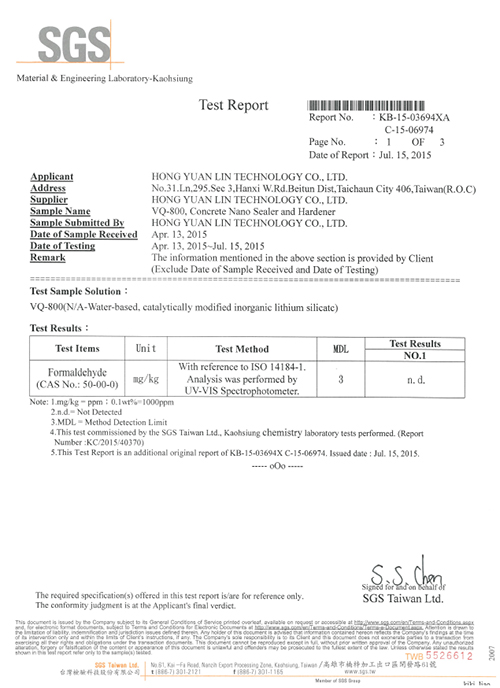

| Eco-friendly | The features of VQ-800 is transparent, non-toxic, and non-flammable, which belongs to eco-friendly materials. |

The Physical Features of VQ800

| Test Items | Test Results | Test Results |

| Hardness | Within 10 days, the MOHS value can level up 3-class. | CNS10631(2008) |

| Anti-abrasion | Within 10 days, the level is raised up to 30% | Within 10 days, the level is raised up to 30% |

| Anti-slide coefficient | Dry:0.6; Wet:0.65 | ASTM D1894-14 |

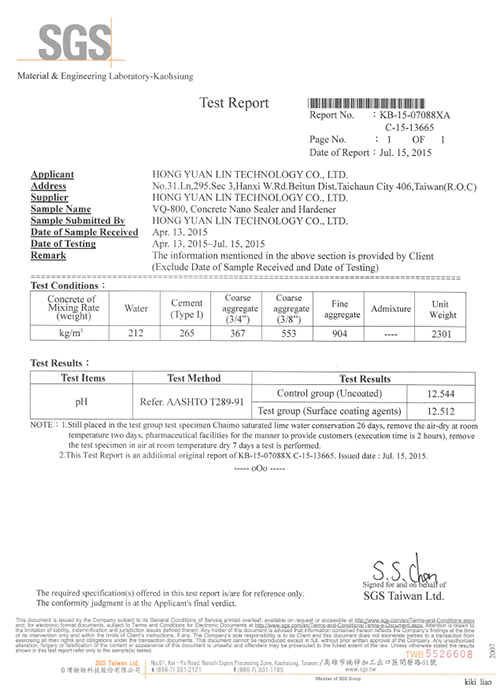

| PH Value | 10.9 | CNS 12002 |

| Eight heavy metal | None | CNS4792-1 |

| Anti-stress | Within 10 days, the level is raised up to 7%. | CNS 1232 |

| Anti-sheer | Within 10 days, the level is raised up to 30%. | CNS 1011 |

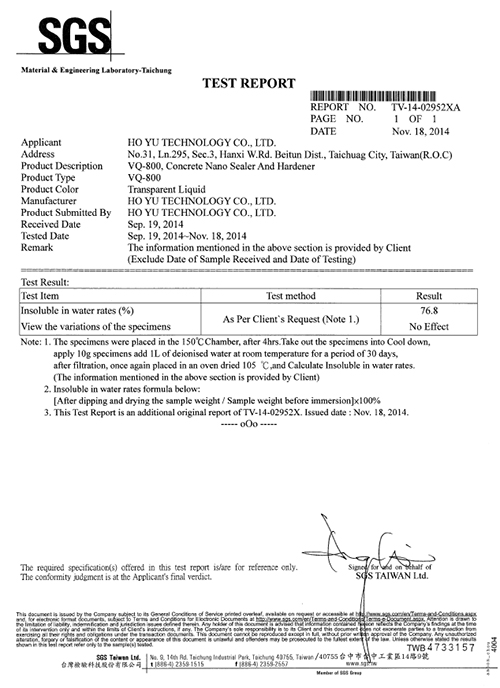

| The ratio of un-dissolve in water | Over 75% | After cured at 150℃ for 4hrs, take 10g amount out and put into 1 litter of de-ionization water; 30 days later, strain off with filter pater then cure under 105℃. Finally, calculate the data of un-dissolve in water. |

| Appearance | No Yellowing | Yellowing test(150℃@4 hrs.) |

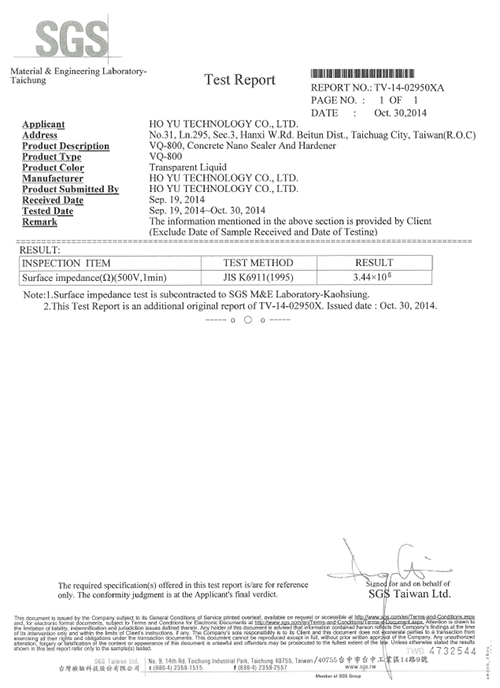

| Impedance | 3.44X106 | JIS K6911(1995) |

VQ-800 V.S. Other Flooring systems

|

VQ-800 Seal Floor |

Epoxy Resin | Abrasion-proof(Wear-resisting )flooring hardener | Granito | PVC flooring material | |

| Basic Requirement | New/old ground all can be used; No need water-proof layer handling before treatment. | Need to make water-proof layer handling initially; if not, it will cause coming off. | Only New surface of ground can be used; old one can not. | None | Requirement for water-proof layer; nor easy to come off. |

| MOHS Scale | Max. 8~9 | 2~3 | 6~7 | 4 | 2.8 |

| Anti-Abrasion | 6.3~20 | 2.3 | 4.6 | 3.3 | 2.1 |

| Anti-permeability/m2 | 0.088 ml/h | 0 ml/h | 200 ml/h | 250 ml/h | 0 ml/h |

| Anti-Ageing | Over 60 years | 3~5 years | 5~8 years | 5~8 years | 2~3 years |

| The period of full cure | Full-cure completely within 1 day. | At least 1 week | 12~14 days | 2~5 days | 3~5 days |

| Safety & Environmental | Conform with VOC standard; environmentally friendly. | Toxic; Non-environmental protection. | A lot of particles generated while handling | Too much contaminants generated during handling | Volatility materials generated while handling |

| Maintenance Fee | Oil-proof, easy clean & without polishing; only clean with soap water. | Oil-stain & scratched are difficult to clean.Polishing Fee is required. | Oil-stain is easy to penetrate; Polishing fee is required. | Oil-stain is easy to penetrate; Polishing fee is required. | oil-stain & scratched are difficult to clean.Polishing Fee is required. |

The construction Plans of VQ-800, the Nano Concrete Densifier, for Dry Grinding

1. Dilute the raw liquid of VQ-800

Use one to three times as much water to dilute the raw liquid of VQ-800 (the ratio of VQ-800 to water is 1 to 1 3). Basically, how many times as much water can be used to dilute with the raw liquid of VQ-800 depends on the quality and density of the concrete itself. The better the quality and the density of the concrete are, the more times the raw liquid of VQ-800 can be diluted.

Use one to three times as much water to dilute the raw liquid of VQ-800 (the ratio of VQ-800 to water is 1 to 1 3). Basically, how many times as much water can be used to dilute with the raw liquid of VQ-800 depends on the quality and density of the concrete itself. The better the quality and the density of the concrete are, the more times the raw liquid of VQ-800 can be diluted.

2. Grind the surface

Use the floor grinder installed with a #30-#60 metal grinding pad to grind the floor and then use the floor polisher installed with a #50-#400 resin polishing pad to polish the concrete floor (dry grinding or wet grinding are both available) so as to make the cement pores exposed thoroughly.

Use the floor grinder installed with a #30-#60 metal grinding pad to grind the floor and then use the floor polisher installed with a #50-#400 resin polishing pad to polish the concrete floor (dry grinding or wet grinding are both available) so as to make the cement pores exposed thoroughly.

3. When to spray VQ-800, the Nano Concrete Densifier

After polishing the floor by using the floor polisher installed with a #50-#400 resin polishing pad, you can start to spray diluted VQ-800, the Nano Concrete Densifier, once on the clean and dry concrete ground evenly (the using amount is about 0.15-0.25kg per square meters). Keep the surface of the concrete floor moisturized in half an hour after treating with VQ-800. Add some diluted VQ-800 on the area of the concrete surface where is dried too quickly in the half an hour.

After polishing the floor by using the floor polisher installed with a #50-#400 resin polishing pad, you can start to spray diluted VQ-800, the Nano Concrete Densifier, once on the clean and dry concrete ground evenly (the using amount is about 0.15-0.25kg per square meters). Keep the surface of the concrete floor moisturized in half an hour after treating with VQ-800. Add some diluted VQ-800 on the area of the concrete surface where is dried too quickly in the half an hour.

4. Grind the treated floor in four hours

After spraying the agent within one hour to four hours, clean all the excess material and then begin to process the next step polishing with the floor polisher installed with the resin polishing pad of next number. For example, if you spray diluted VQ-800 after polishing the floor by using the floor polisher installed with a resin polishing pad of 50 grits, wait for at least an hour and then polish the floor by using the floor polisher installed with a resin polishing pad of 100 grits within three hours. Please don’t polish the concrete floor 4 hours later after the floor is treated with VQ-800, or the floor will get too hard to polish.

P.S. If you can’t polish the ground in four hours after spraying the diluted VQ-800 on the concrete ground, please use water or the floor polisher to remove the residues of the diluted VQ-800 first.

After spraying the agent within one hour to four hours, clean all the excess material and then begin to process the next step polishing with the floor polisher installed with the resin polishing pad of next number. For example, if you spray diluted VQ-800 after polishing the floor by using the floor polisher installed with a resin polishing pad of 50 grits, wait for at least an hour and then polish the floor by using the floor polisher installed with a resin polishing pad of 100 grits within three hours. Please don’t polish the concrete floor 4 hours later after the floor is treated with VQ-800, or the floor will get too hard to polish.

P.S. If you can’t polish the ground in four hours after spraying the diluted VQ-800 on the concrete ground, please use water or the floor polisher to remove the residues of the diluted VQ-800 first.

Preliminary Polishing

Polish the floor thoroughly by using the professional polishing machine with 400#-800# resin polishing disc two or three times.

Polish the floor thoroughly by using the professional polishing machine with 400#-800# resin polishing disc two or three times.

Fine Polishing

Polish the floor thoroughly by using the professional polishing machine with 800#-3000# resin polishing pad two or three times. Clean up the surface after polishing and just allow it to get dry naturally.

Polish the floor thoroughly by using the professional polishing machine with 800#-3000# resin polishing pad two or three times. Clean up the surface after polishing and just allow it to get dry naturally.

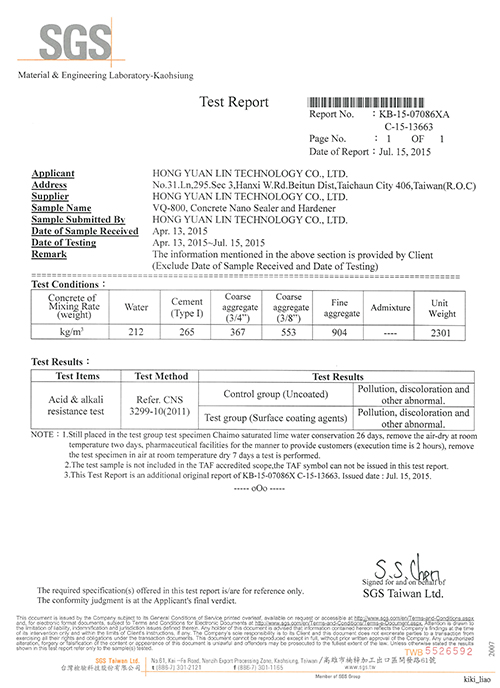

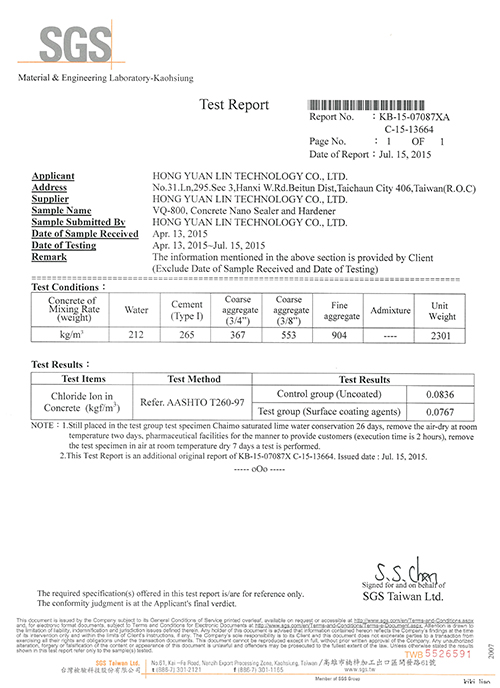

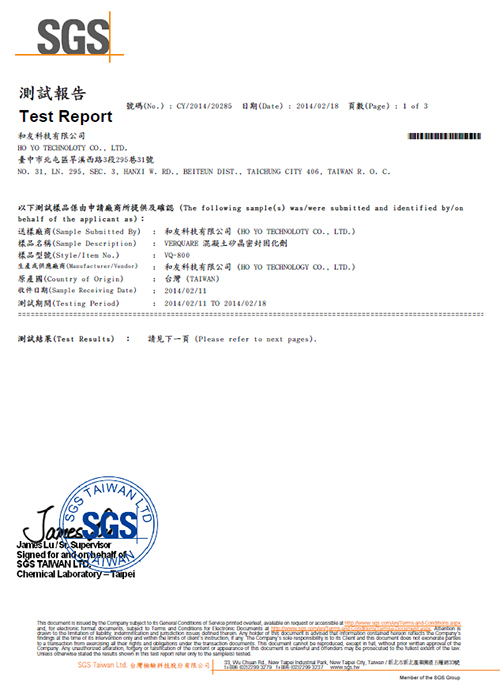

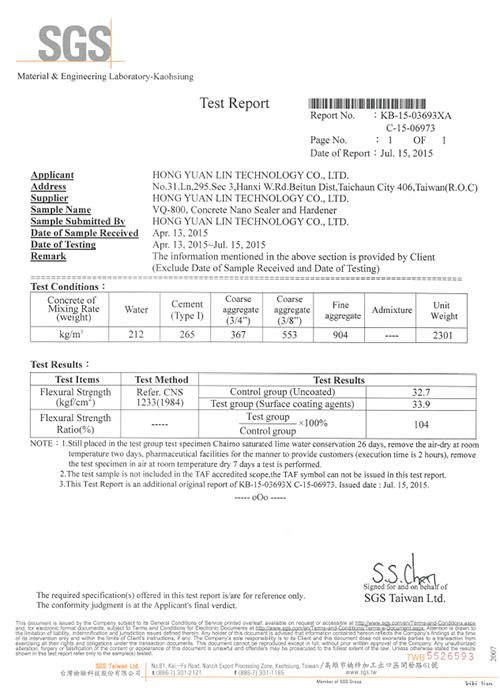

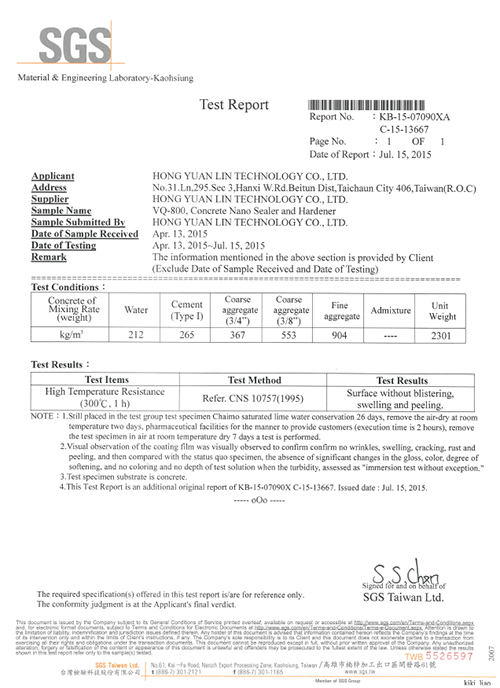

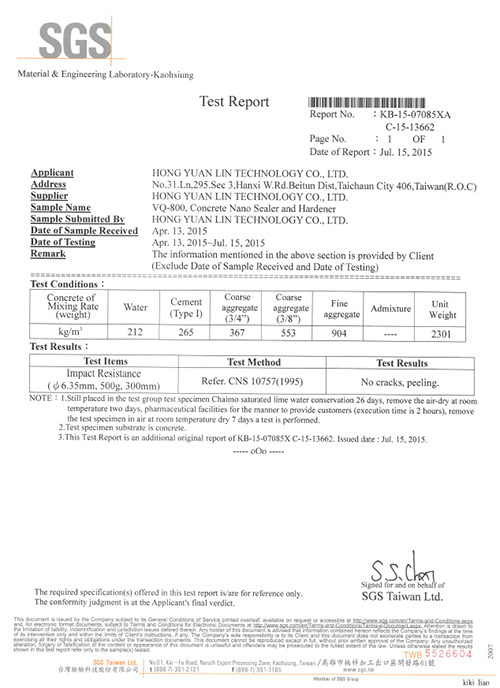

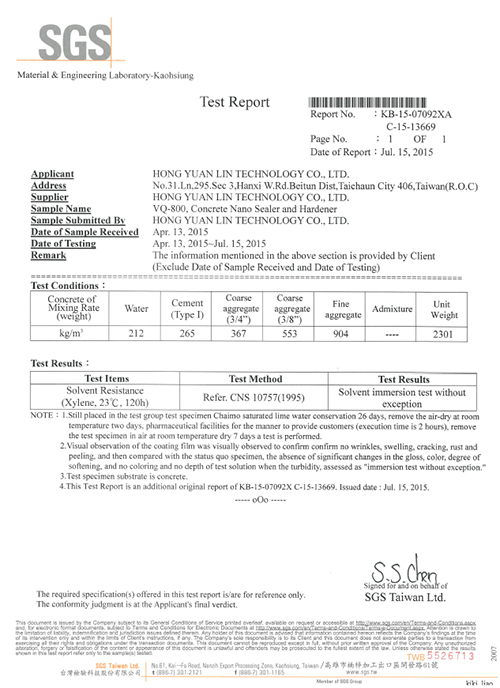

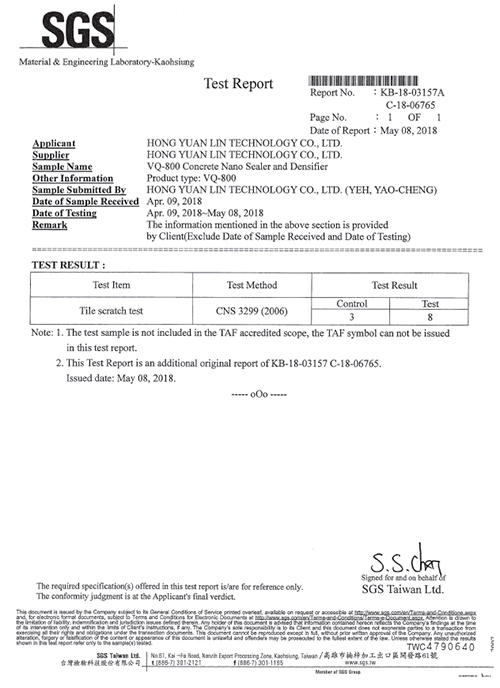

VQ-800 Test Report

產品問與答