●Poor Duration: only adhere to the surface of the wall or the brick, which can’t penetrate into the substrate to do the reaction. The effect of water repellence will decrease gradually after raining and wind blowing, so the effect or water repellence usually can’t last more than 6 months.

●Easy to get polluted: Containing organic components inside and easy to be decomposed by ultraviolet rays, and this will create a lot of tiny molecules which will adhere to the wall strongly and form the black spots on the wall which might pollute the wall and not easy to get rid of.

1. Fill up the cracks on the surface of the substrate first. All the surfaces of the substrate must be clean and dry. Clean up all the dirt, grease, moss, and old coating on the surface and make all the surfaces of the building totally dry so as to make VQ-1006 penetrate into the substrate thoroughly.

2. Roll, paint, or spray a layer of VQ-1006 from up to down the substrate.

3. It must be taken over 24 hours to allow the surface of the substrate to be touched by water after the application of VQ-1006. (The time can be shorten by the exposure to sunlight to increase the reaction.)

4. Clean up the wax left on the surface of the substrate by using the cold solvent degreasing agent if the substrate was ever polished or waxed. After applying VQ-1006 on the smooth surface of the stones for 30 minutes, please wipe out the excess agent of VQ-1006 with dry rag.

1. Non-yellowing, no polluted spots left, all the dirt will be get rid of after raining or washing the wall.

2. High penetration, great consolidation, long durability.

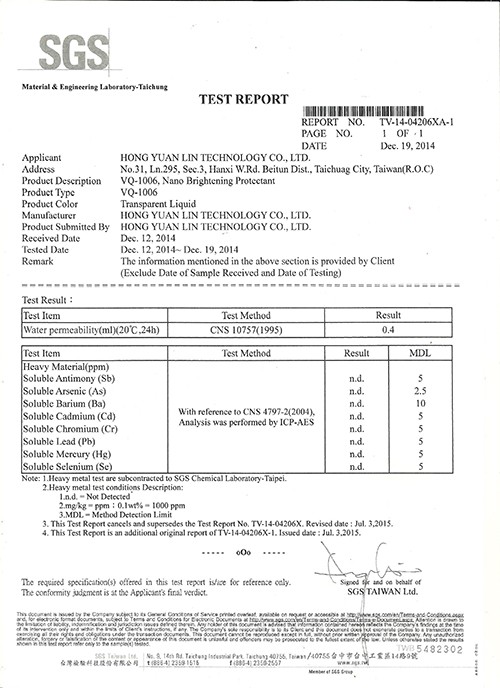

3. Good water repellence, prevent water penetration efficiently.

4. It is suggested to repaint the new layer every three years so as to maintain the effect of water repellence and dust proof.

5. With the south wind’s blowing, the wall can avoid the water condensing.

1. VQ-1006 can be applied neither on the surface which holds the water pressure directly nor for the protection of the back side of the stones.

2. Never apply the agent of VQ-1006 on rainy or cloudy days.

3. If you have to apply the agent of VQ-1006 on the substrate twice, please process the second procedure before the first layer of VQ-1006 applied on the substrate get totally dry. Never pile the substrates together before VQ-1006 applied on the substrates get dry.

4. The constructers must wear the helmet, safety goggles, and plastic gloves while applying the agent of VQ-1006.

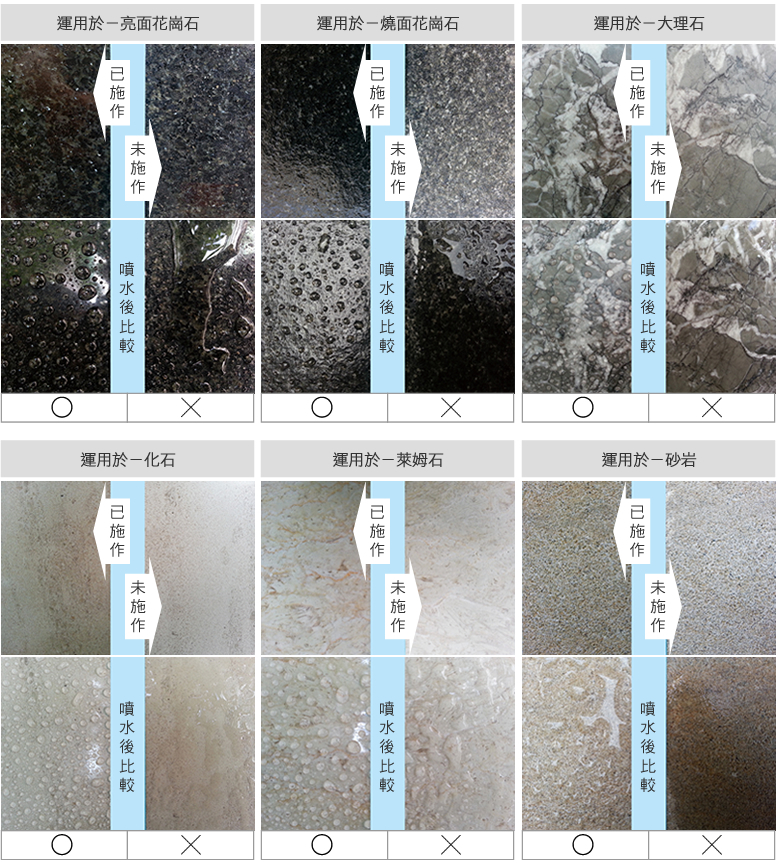

5. Due to there are various kinds of stones, we suggest that you can choose a little and unobvious part of the substrate to be tested by the agent of VQ-1006 to see if the effect can be satisfied by you. If the trial can achieve your expectation, then you can apply the agent of VQ-1006 doubtlessly. While applying VQ-1006 on granites or stones with dark color, it may brighten the color of the substrate at first, but the brightening effect might get faded gradually as time goes by. And, due to the voids of the marbles, sandstones, and fossils are bigger, the brightening effect might not be so obvious.

6. Before application, please wrap the other surfaces of the substrate which won’t be applied with VQ-1006 first, if you spray VQ-1006 accidently on the surfaces which are not supposed to apply VQ-1006 on it, just use dry rag to clean it up.